Contact: A. Tirella [email protected]

Aim

Realisation of high quality and precise pattern with a non-contact nano-dispensing CAD/CAM system: using a patented thermal ink-jet technology (BioJet system, R&D Olivetti I-Jet, Arnad, AO), it is possible to precisely and accurately dispense picoliter to nanoliter volumes of liquid. Depending upon chosen printhead and biological fluid, optimal printing parameters can be set: driving energy, printing frequency, pulse length. Different bio-molecules were printed with this system (i.e. genipin, albumin-FITC), as well as nano-particles (NP) and cells (i.e. fibroblast, hepatocyte, endothelial).

Results

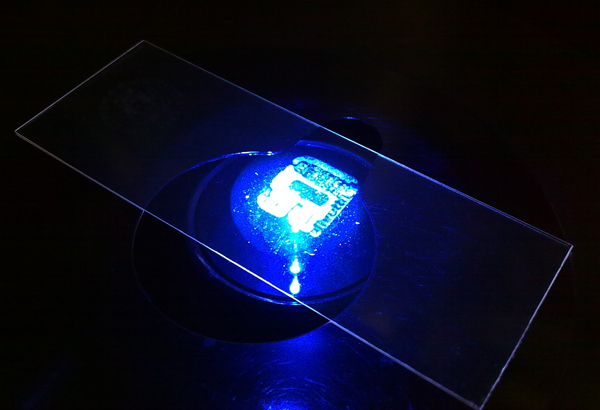

Different pattern were printed with BioJet system. As show in figure 1 a pattern was printed using NP labeled with FITC, or as shown in figure 2a-b other patterns were printed using albumin-FITC solution.

Figure 1. Olivetti and leaning tower logo printed using nano-particle labeled with FITC

Figure 2a. Hexagonal pattern of albumin-FITC: 4 drops of 160 pL per side

Figure 2b. University of Pisa logo “cherubino”realised with albumin.FITC

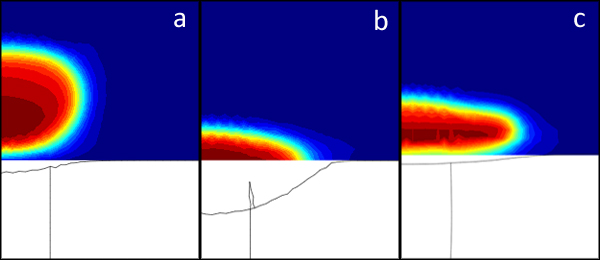

Other experiments were performed printing cells. Recently we investigated the influence of the deposition surface mechanical properties in printed cells viability. A Finite-Element Model (FEM) was realised to evaluate the impact force of a droplet ejected with BioJet system varying the substrate properties. Different substrates were investigated with the FEM model: from a rigid (polystyrene) to a liquid deposition substrate (cell culture medium). As shown in figure 3 impact force decreases with the mechanical properties of the deposition surface.

Figure 3. Droplet shape before the impact (a). Droplet shape and substrate deformation after the impact with different surfaces: a) collagen, b) polystyrene

Fibroblasts were printed with BioJet system onto different substrates to confirm FEM results. Cell viability was evaluated 4, 24, 48 hours after the printing. Particularly it seems that a rigid surface causes damages which can be partially recovered only after 48 hours. Visco-elastic or viscous solution influence cell viability only during the first 4 hours after the printing process and then the proliferation rate is almost the same compare to the control.

Publications:

Tirella A., et al. Importance of cell-substrate impact during drop-based deposition, NIP26-DF2010 Congress